Japanese Saws

Japanese saws cut on the pull stroke, so that the sawing action holds the blade in tension as you cut. This means the saw blade can be thinner, so less material needs to be removed and you make faster progress with less effort.

Japanese saws fall into three broad categories, they sometimes come in different lengths, in general the longer the saw the coarser it is - better for cutting larger workpieces.

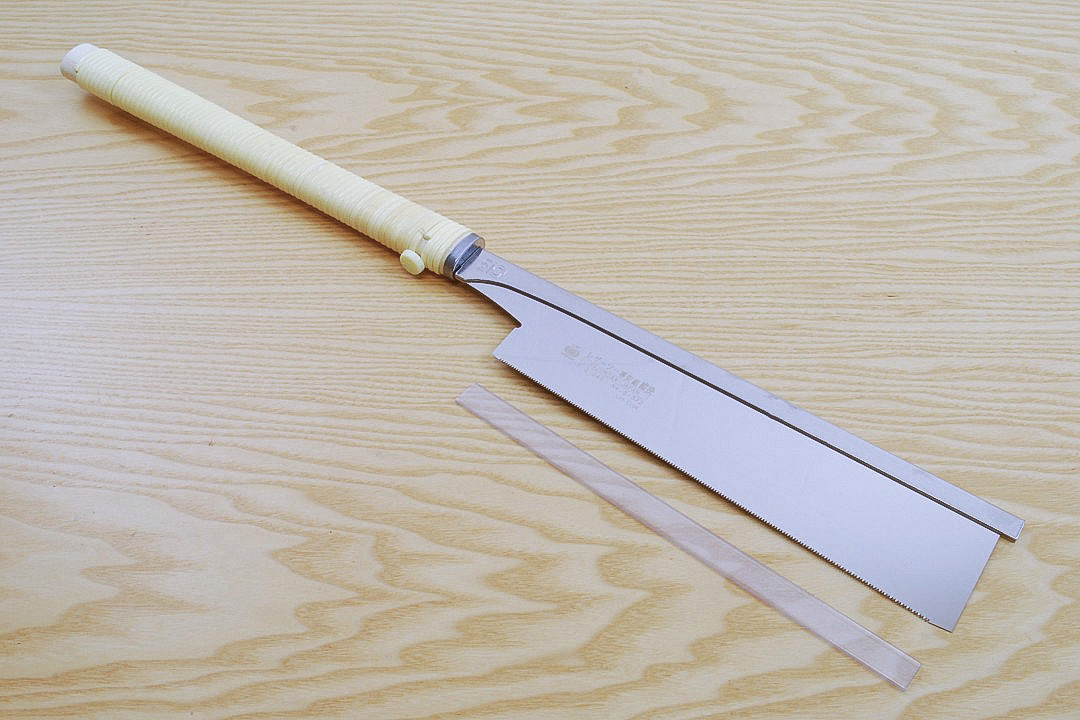

• Dozuki (back saws) have very fine blades and are primarily for precision work.

• Kataba (backless saws) are for deeper cuts, beams, panels, etc.

• Ryoba (double edged saws) have different tooth patterns on either side of the blade, usually one for ripping and the other for crosscutting and are the most widely used Japanese saws. These are available in a wider range of subtypes including:

• Bluehard (stiffer plate, more accuracy for joinery work, slightly less forgiving of misuse)

• Komame (finer teeth, better if most of your work is in harder woods)

• Seiun (standard teeth, better if cutting softwoods and milder hardwoods)